Evolution Racewerks Competition Series BMW N55 Front Mount Intercooler (F Chassis)

From $895.00

Starting at $56/mo or 0% APR with Affirm. See if you qualify

Key Features:

- Designed specifically to fit (and look good) on the 335i and 435i.

- Large 20"x11"x3" (26"x11"x3" with end tanks) High Density Bar & Plate Construction Intercooler Core

- Cast end tanks for improved durability and internal flow characteristics.

- Brush finish standard

- Optional Polished finish available.

- Optional Type III Hard Black Anodizing (for stealth) finish on intercooler, end tanks and all piping. Hard anodizing helps improve durability of intercooler fins against damage from road debris (rocks).

- Features the factory style connectors. Fully compatible with factory piping or aftermarket piping utilizing factory style connectors. Compatible with our charge pipe upgrade kit.

- Maintains ALL factory components. No modifications required. 100% bolt on.

- Includes all hardware needed to install.

- Developed and tested for over a year under the harsh conditions of racing.

- Limited Lifetime Warranty.

Competition Series FMIC Installed

Factory Intercooler versus Competition Series FMIC

The heart of the ER Competition FMIC is the massive 20"x11"x3" (26"x11"x3" with end tanks) featuring our famous high density bar and plate intercooler core. It features 660 cubic inches of very efficient high density bar & plate core (35% larger) versus the factory 425 cubic inches of less efficient tube & fin core. Through extensive testing of different types of intercooler cores (tube & fin, bar & plate) we developed our own high density bar and plate core. What's different about our bar and plate core you ask? Fin density. Why is this important? The fins are the main heat transfer surface. More fin density = more actual surface area. What does this mean in the real world? Most quality intercooler cores utilize around 12-14 fins per square inch. Cheap quality oversea cores utilize around 8-10 fins per square inch (some even lower) which explains why they perform so poorly even though a large core is utilized. Our Evolution Racewerks cores are 18-20 fins per square inch. What this means is that compared to a cheap overseas core, we can get the same efficiency in roughly half the core size. Now imagine if they're the same size!

Factory Intercooler Core

Factory Intercooler Core

Evolution Racewerks High Density Core

Independent testing (by customers and shops) throughout the years have shown that time and time again, our intercooler cores have outperformed our competitors. We've even had competing companies utilize our intercoolers for competition instead of their own! The independent test data below shows that our FMIC is so efficient in cooling that it has cooled intake air temperatures (IAT) to almost ambient (outside) temperatures. We also did extensive testing on the proper size to use to effectively cool the hot charged air as well as fight off heatsoak (when the intercooler cannot transfer heat away faster that the heating building up from the hot intake air). Heatsoaking is not an issue at all as shown by the consistency of the IAT staying in the same temperature range throughout the WHOLE RPM powerband. Also, our FMIC recovers so quickly after a full throttle pull that once you shift, it recovers completely. This is why pull after pull, our FMIC does not heatsoak. Beat on it all day long and the IATs will consistently stay the same. Our Competition FMIC is just what it is called, designed for competition. Other brand intercoolers may be adequate for short period pulls like the 1/4 mile (with hours between runs to cool down). Our intercoolers are designed to withstand the rigors of harsh racing conditions like road racing where you are at full throttle for long periods of time, sometimes behind other cars blocking direct airflow needed to cool down your intercooler. With countless test and competition laps around our local racetracks in 100+ degree weather, heatsoak is not a problem on our 135i Time Attack race car. With it's size and ability to support over 600hp, it is most likely the "last intercooler you will ever buy".

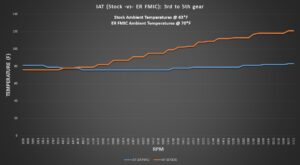

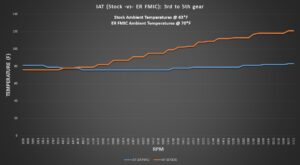

4th Gear Pull. Outside temperature of factory intercooler run was 63F. Outside temperature of Competition FMIC run was a hotter 70F. Factory intercooler already heatsoaking (over 40F difference) from a single gear pull! (Independent test data from JustinCredibleM)

3rd Gear to 5th Gear Pull. Outside temperature of factory intercooler run was 63F. Outside temperature of Competition FMIC run was a hotter 70F. With the factory intercooler, heatsoak is easily shown on the graph by the constant upwards climb of the IATs. With our Competition Series FMIC, the IATs are stable, indicating heatsoak under control. (Independent test data from JustinCredibleM)

One of the most overlooked aspect of intercooler design is the intercooler end tank and piping. Having shorter and less bends on the intercooler piping will promote better internal flow. This helps in reducing turbo lag, increase throttle response and faster boost spool ups. An intercooler end tank must be designed to channel and distribute air coming in from the inlet efficiently throughout the intercooler core. Our end tanks are designed to promote smooth internal air flow. The cast end tanks allow us to have nice smooth radius on the inner edges of the end tank, causing less turbulence.

One of the first things we noticed when we started development of our Competition Series FMIC for the F Series Chassis cars is that there is much more space behind the bumper cover compared to the older E Series Chassis cars. Without any major space restrictions, we chose to move the intercooler forward from the factory location. This allowed us to have an intercooler with more frontal surface area and more direct airflow without having to sacrifice internal airflow with an odd shaped end tank. Our test data on this design showed improvements in both IATs and ability to fight off heatsoak. Another added benefit of moving the intercooler forward is that now, intercooler sits more aggressively behind the center bumper cover.

Additional information

| Finish: | Brushed, Polished, Type III Anodized Black |

|---|---|

| Model: | M2, All other F Chassis Models (1/2/3/4) |

| Transmission: | Automatic, Manual |

| Drivetrain: | RWD, AWD |

Only logged in customers who have purchased this product may leave a review.

Related products

-

Wagner Tuning Competition Intercooler MB (CL)A-B-class EVO1

$1,140.00 -

Wagner Tuning Competition Intercooler Kit EVO 1 BMW F2X F3X N55 N20 N26 N13

$490.00 -

Wagner Tuning Aluminum Charge Pipe B58 Gen 2 BMW/Toyota

$490.00 -

Wagner Tuning Performance Intercooler Kit Mercedes C190 AMG GT Base S C R

$3,440.00

Reviews

Customer reviews

There are no reviews yet.